Save Upto $850 ›

Save Upto $850 ›If you have a gas stove, then you may have observed a vertical gas pipe running to your gas stove and wondered what the heck is this or is this of any use or not. This is a sediment trap and it very useful.

A sediment trap is an essential element for installing a gas stove in your kitchen so that it performs efficiently.

As per California Building Code, 2016, it is compulsory to install a sediment trap vertically to all types of appliances that requires gas to operate.

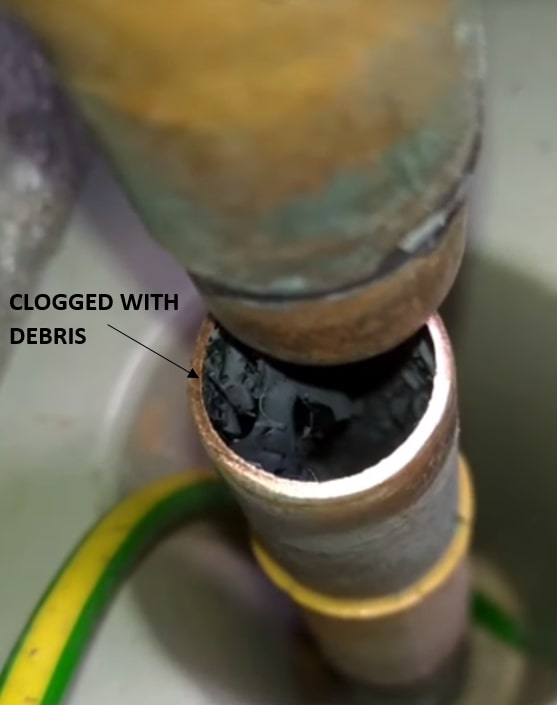

Sediment traps are purposely installed to help prevent debris/clogged sediment to get into gas valve or burner area of a through gas piping and fouling things up.

A gas line sediment trap is used to trap any kind of debris in the line and help these kinds of wastages to go into your gas cooktop.

There is a lot of misunderstanding regarding sediment traps, despite the fact that they have long been necessary for gas piping systems. Continue reading to find out what they are exactly, where to install them, and how to configure them correctly.

As per the building codes of California Building Code, 2016:

“G2419.4 (408.4) Sediment Trap

Where a sediment trap is not incorporated as part of the appliance, a sediment trap shall be installed downstream of the appliance shutoff valve as close to the inlet of the appliance as practical. The sediment trap shall be either a tee fitting having a capped nipple of any length installed vertically in the bottommost opening of the tee as illustrated in Figure G2419.4 or other device approved as an effective sediment trap. Illuminating appliances, ranges, clothes dryers, decorative vented appliances for installation in vented fireplaces, gas fireplaces and outdoor grills need not be so equipped.”

You can check the full building code Guideline here.

But you may be asking why these traps are that much important? Well, as told before, these sediment traps are used to prevent any kind of clogging into your gas stove. That is why the United States has made it mandatory to use them with any appliance that functions on heating i.e. furnace, boiler, heater, gas stoves etc., to help you avoid any calamity.

Moreover, as you know the gas stoves are very and cost a fortune to be replaced. Therefore, you want them to last as long as possible.

A Sediment, hence, is the best approach. It helps your gas stove get rid of all kind of wastage and extends its life. That is why it is also known as drip leg or drip tee.

First of all, it is compulsory for you to call a professional to install a gas stove sediment trap, if you are not a DIY yourself. He will charge you for about $100, or if you want to try it by yourself then you can get a kit at the local hardware store for about $10.

Here have a look at this video, if this seems easy to do then you can make a sediment trap by yourself.

We again want to stress that the above mentioned video is provided just to give you some helpful insight on how things work and you should not try to do anything by yourself, unless you have quite good expertise or are a licensed plumber/PR actioner in the subject matter.

Many people think that if the person installing gas stove has not asked to install a sediment trap then it is not really necessary, which is utterly wrong.

Many plumber or HVAC technicians, themselves, does not have a clue how, when and why a sediment trap is installed. So, we’d recommend you to hire a plumber from a reputable firm and also ask him to install a sediment trap.

If it is really not that necessary then he’ll let you know otherwise he’ll install it.

If the gas stove did not come with a sediment trap, it can be installed.

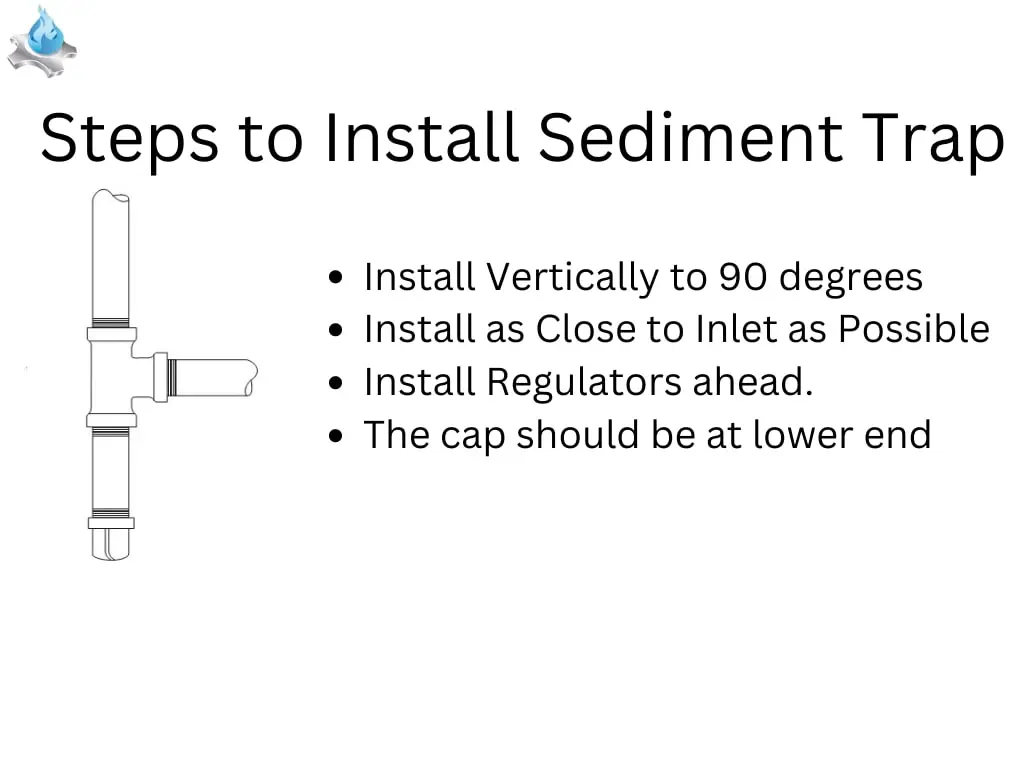

However, if there are some rules that must be complied with when installing a sediment trap:

It is also pertinent to mention here that the old language code required sediment traps to be installed dropped down to the appliances, but that is no longer the case.

As per Chapter 2 Fuel Gas Code 2012 of Montana:

“APPLIANCE, AUTOMATICALLY CONTROLLED.

Appliances equipped with an automatic burner ignition and safety shutoff device and other automatic devices which accomplish complete turn-on and shutoff of the gas to the main burner or burners, and graduate the gas supply to the burner or burners, but do not affect complete shutoff of the gas.”

Check the full guide here

To make it clearly understandable, it can be described in such a way that the sediment traps are required in furnaces, boilers, water heaters, clothes dryers, ovens, space heaters, unit heaters, gas fireplaces, and other appliances.

Despite these criteria, We, being the professional in the instant case, have never seen one placed at a gas fireplace, they’re practically never installed. However, you should not neglect the fact that they are required to be installed by the code of conduct.

Don’t be concerned if your appliance does not have a sediment trap. It is not a major issue. Simply plan on having it fixed the next time the appliance is replaced. Or not. It’s probably not a major concern if it’s not corrected. If you hear someone making a big deal out of it, encourage them to focus on something more important, like dinner.

This is a really simple but somewhat perplexing topic. Many home inspectors, as well as many plumbers and HVAC technicians, use the phrases interchangeably and are unaware of the distinction. When we emphasize the need for and lack of a sediment trap, the ordinary home buyer gives a blank stare (obviously not knowing what it is).

Sediment traps are located in the gas supply line between the gas shut off valve and the controls of gas heaters, water heaters, and pool/spa/hot tub heaters.

The image below depicts a water heater in use without a sediment trap.

Begin with a short nipple coming from the control unit, then add a “T” and tighten until the “T” is vertical. Insert another nipple (maximum than 3”) on the bottom of the “T” and cap that nipple. Connect the flexible gas line from the shut off valve to the top of the “T.” A well designed sediment trap is shown above.

Obviously, this does not apply to electric equipment, and sediment traps are not required for all gas appliances. Gas stoves, cook tops, and fireplaces, for example, are not necessary.

A sediment trap’s aim is to keep any silt that may be in a gas supply line from entering the controls of a heater or water heater. When installing or updating these units, a plumber or HVAC technician will typically build them on the spot. I’ve never seen a man-made sediment trap, but they could exist.

Drip Legs appears to be very similar to a sediment trap. It is in a T shape just as the sediment trap but it is positioned horizontally with one opening facing downwards.

The terms “drip leg” and “sediment trap” are frequently used interchangeably, however they are not interchangeable. Drip legs (officially referred to as simply “drips”) are installed to collect condensation in a gas piping system, and they are installed at a low point to prevent condensation from running back into the gas meter.

Are you wondering why you’ve never seen one of these? They are not necessary where the local gas utility produces “dry gas,” defined as “a gas with a moisture and hydrocarbon dew point lower than any normal temperature to which the gas piping is exposed.”

Point to Ponder: A sediment trap will catch moisture just as efficiently as a drip leg, however a drip leg may miss microscopic pieces of sediment. Although no one ever does it, occasionally removing the bottom cap from the sediment trap and tapping it to knock out the trapped sediment is not a terrible idea.

If you liked our article so far then subscribe to our newsletter and get the best of tips and tricks directly into your inbox.

A Drip Pocket in a piping system is designed to catch condensate and allow the condensate to be evacuated. According to the Code mentioned above, drip pockets should be installed at the bottom of a piping system or on the final drop to an appliance.

CSST tubing, also known as corrugated stainless steel tubing, is ideal for gas appliance installation. Because corrugated pipes bends around curves, reducing the number of connections and joints. It is lighter and easier to deal with than steel pipe.

A stub out is a section of pipe that extends from the wall to attach appliance to it. If you are not using a gas stub out then you can cap until you need it

Drip traps are connected to a Sediment Trap for further efficiency or to collect and safely remove liquids from low locations in gas control lines.

So, now that you know the importance of sediment traps, it is again forced that you get the sediment traps installed before installing your gas appliance and all the process must be done by a professional hired from reputable company.